Skill Saw Guide Diy

As well as that, this saw guide is suitable for all workpieces with lengths from 8 cm up to 136 cm. The wide piece would form the base, the thin piece the fence to run the saw against while making cuts, and the trim piece would help form a lip on.

Homemade Sliding Circular Saw Crosscut Guide DIY

Homemade Sliding Circular Saw Crosscut Guide DIY

The price of the circular saw depends on the quality of it.

Skill saw guide diy. January 18, 2016 at 7:58 pm. See more ideas about woodworking shop, woodworking jigs, diy woodworking. It’s kristen, from in her garage, and today i am going teach you how to make a diy track saw jig for your circular saw.it’s basically a super simple circular saw cutting guide to make rip cuts much easier for you.

Get the straightest board you can find, and don’t be afraid to compare boards to get the best one. Overview of creating this diy circular saw guide system. Rip the base piece about 12 inches wide and make the fence 3 inches wide.

Cutting along a straight line is a skill saws that takes practice. Make the base's cutting side about 1 ⁄ 2 wider than the distance between your saw's blade and the footplate edge below the motor. With a simple accessory, we found that you can get table saw clean cuts when you’re using a circular saw provided you have the best circular saw guide rail for your needs.

You can complete both in two or three hours from one sheet of mdf or plywood. While you’re at the store, get an 8′x12. So glad i could help!

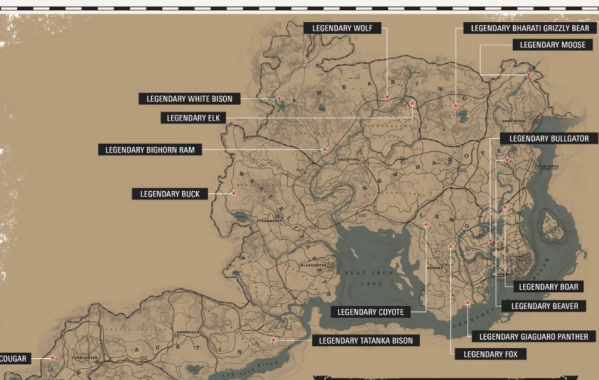

Your saw might have more lines, or a laser, or any number of other bells and whistles. Here are instructions for building a basic, circular saw guide for long, straight cuts: The best way to make square, straight crosscuts on lumber or plywood with a circular saw is by using a homemade crosscut guide.

Although it is not required, you might also want to have some primer and paint to coat the saw guide. They have a reputation for tearing up boards pretty good, even when used properly. For my 5 1/2” ryobi circular saw, i chose to use 1/4” plywood for both boards.

A guide rail can come with multiple functions. You could easily make this saw guide with a 2 ft. To make a crosscut guide for your circular saw:

Don’t try to steer the blade back onto the line. A circular saw a guide rail is a tool that aids saw to cut the wood into various parts and give a new shape. We took the time to figure out which were recommended, test them out.

Pm tells you how to build a your own circular saw guides the guides are compact for easy storage and most importantly, they can help you work more accurately and safely in the shop. A hardboard circular saw guide that is made custom for my circular saw. Diy track saw jig for your circular saw.

Here are some of the things that i love about this system: The opposing side of the guide marks the outside edge of the blade when the saw is set to 45 degrees. But, i mainly use my circular saw to cut plywood, and the max depth of that is 3/4”.

Head to the hardware store to pick up supplies. The tools used in manufacturing the rails guide are mostly costly, so usually, these rails are expensive. Easy & accurate cuts first go, thanks to this handy homemade saw guide which will save you time, every time.

Be sure to have excess plywood on both sides of the glue joint. Guide to optimum sawing results you’ll get perfectly straight and accurate 90º and 45º cuts with the skil saw guide. Diy circular saw guide from scrap wood i used just three random pieces of leftover wood from past projects (the bedroom chest and a piece of trim that i used to cover a weird edge on my ceiling ).

Start by building a jig based on the drawing below; From now on, using your circular saw to make perfectly straight cuts in sheet materials will be as simple as measuring two pencil marks and clamping the guide in place. With these two saw guides, you can use your circular saw to make cuts that rival a table saw’s for speed and accuracy.

With the help of this saw guide there’ll be a maximum deviation of only 1 mm per metre. Circular saws use round blades with evenly spaced teeth to make fast cuts in sheet materials, including sheet metal. Diy track saw using a cheap circular saw:

One side of the guide is for the outside edge of the blade when the saw is set to 90 degrees. Building the guides is a quick and easy project. Choose between corded and cordless options depending on where you plan to work and the amount of power you'll need.

When it comes to clean cuts, not many people think of a circular saw. I had the same dilemma in my workshop, and the circular saw was the best choice for now. The table includes a removable panel where the saw attaches, so t…

Capable of making rip cuts and cross cuts as well as cutting bevels, they're a versatile tool that can be used with a wide range of blades to tackle different tasks and materials. Cut a thin piece of the plywood with the circular saw and attach it to the top of the rest of the plywood using wood glue. But if you get off to a crooked start, it’s difficult to guide the saw back to the line.

Like everything else necessity creates a need, and in this case i needed to be able to cut long straight repeatable cuts on 18mm or thicker plywood. How to make a saw guide. Can i cut more with this.

The fence of this guide will require a 1×4 that is 8′ long. Once the saw blade is aligned and cutting along the line, it doesn’t take much effort to keep the blade on track. Place the circular saw on one side of the straight edge and cut the excess plywood.

And the max depth my saw can cut is a 2×4, which is actually 1 1/2″. Or, it could be as simple as the two shown. Each type is tailored to a different task, with a variety of blade diameters and cutting depths to tackle the demands of the project.

Flip the board and repeat on the other side of the circular saw. Two guides took about an hour to make, and that included a coffee break. Guide the circular saw along the fence to trim the base to the proper width.

Cut a piece of 1”x 4” lumber the length you want to crosscut plus about 6” (we made our guide 18” long for crosscuts on boards up to 12” wide). Bora 100” wtx ruled clamp edge saw guide for woodworking, contractors, carpenters and diy, guide for circular saws, 100 inch cutting length, 545100 4.4 out of 5 stars 26 $109.00 $ 109. Glue the fence to the base, positioning it ½ inch beyond the saw's offset dimension.

Adjust the width as needed for your saw. A power saw can be used to effortlessly cut through metal, wood, aluminium and masonry. But my workshop is too small for a table saw so a circular saw is the best choice (with your diy circular saw guide).

Screws, a screwdriver, two clamps, a framing square, and a circular saw. That means my guide will be a bit flexible compared to thicker wood, but the glue up makes it sturdy enough. I made two guides and had lots of material left over for about $13.

DIY Circular Saw Guide Circular Saw Tips, Jigs and

DIY Circular Saw Guide Circular Saw Tips, Jigs and

DIY Circular Saw Guide Circular Saw Tips, Jigs and

DIY Circular Saw Guide Circular Saw Tips, Jigs and

DIY Circular Saw Edge Guide Circular Saw Tips, Jigs and

DIY Circular Saw Edge Guide Circular Saw Tips, Jigs and

Shopbuilt Guide Rail System Plans Circular saw track

Shopbuilt Guide Rail System Plans Circular saw track

DIY Circular Saw Guide carpinteria Mesas de trabajo

DIY Circular Saw Guide carpinteria Mesas de trabajo

Homemade Circular Saw Jig YouTube Circular saw jig

Homemade Circular Saw Jig YouTube Circular saw jig

How to Make a Motorized Sliding Saw at home in 2019

How to Make a Motorized Sliding Saw at home in 2019

Easy DIY Circular Saw Track Saw Guide FREE PLANS in 2020

Easy DIY Circular Saw Track Saw Guide FREE PLANS in 2020

simple fixed angle saw table Woodworking, Circular saw

simple fixed angle saw table Woodworking, Circular saw

DIY Circular Saw Guide Circular Saw Tips, Jigs and

DIY Circular Saw Guide Circular Saw Tips, Jigs and

Circular Saw Crosscut and Miter Jig Circular Saw Tips

Circular Saw Crosscut and Miter Jig Circular Saw Tips

circular saw straight edge guide Google Search

circular saw straight edge guide Google Search

DIY Circular Saw Guide Circular Saw Tips, Jigs and

DIY Circular Saw Guide Circular Saw Tips, Jigs and

DIY Circular Saw Guide Circular Saw Tips, Jigs and

DIY Circular Saw Guide Circular Saw Tips, Jigs and

Woodworking Projects for Beginners Woodworking projects

Woodworking Projects for Beginners Woodworking projects

Making a Self Clamping Circular Saw Guide Kendinden

Making a Self Clamping Circular Saw Guide Kendinden